Meat Sector Roadmap

Towards an integrated circular sector

Oct 11, 2014

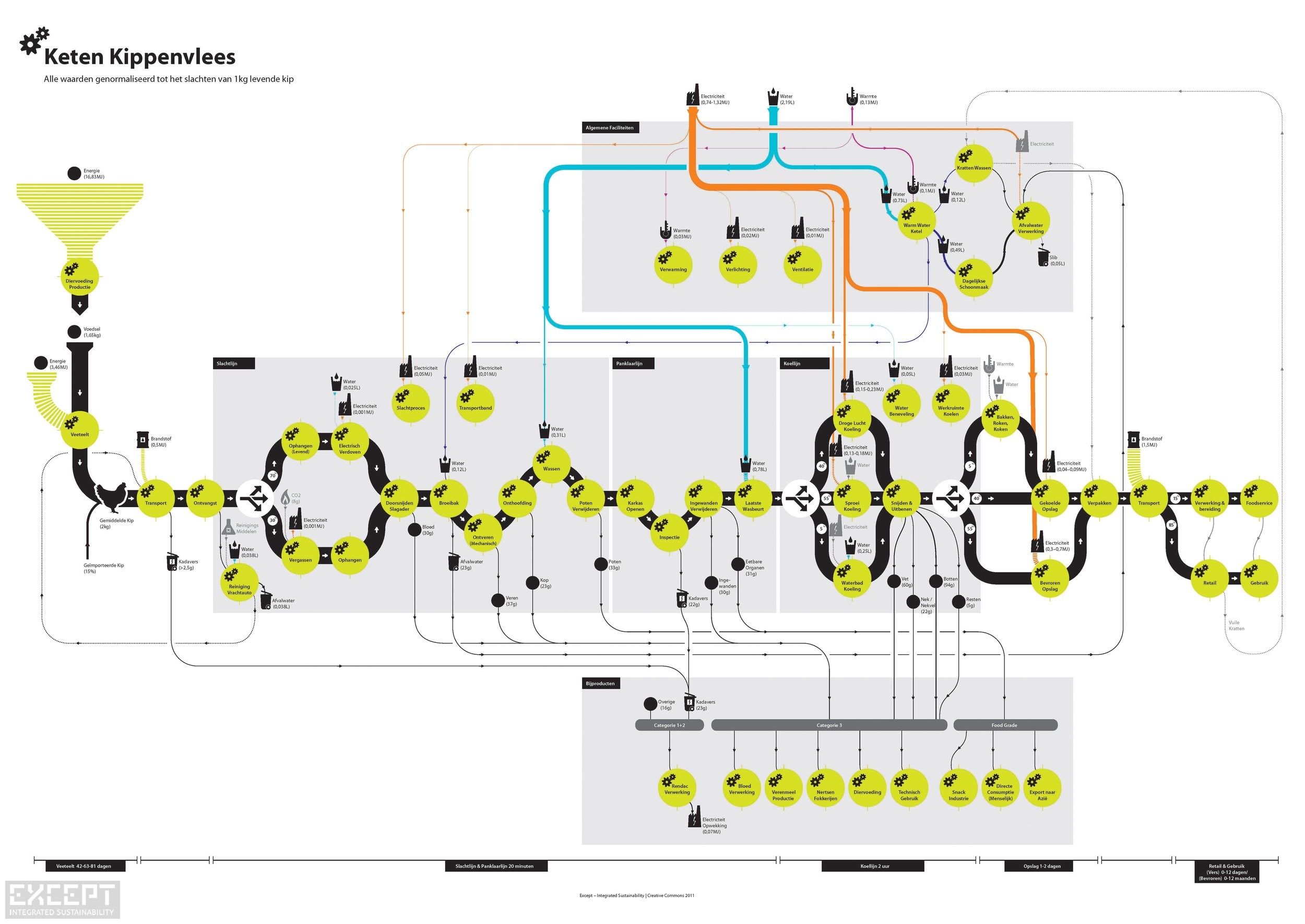

This project developed a roadmap of the meat processing sector in the Netherlands, including production and processing companies and their suppliers. We partnered with DNV, experts in assurance and risk management, to explore and portray opportunities to optimize the energy and material flow of the chicken, pork, and beef supply and processing chains. The maps we developed give an insight into stakeholders and help improve decision-making across the entire production chain.

At the end of our project, we found that two main factors are causing negative impacts to the environment and resource use that affect the sector's sustainability:

Freezing is highly energy-intensive, and the decentralized cooling system adopted by most nodes during the process is powered using inefficient refrigeration systems. In regards to spoilage, it's not always in the supply chain. Results show that wastage of food in households is unnecessarily high.

Meat products have high embodied energy and require large amounts of water to produce. Mapping product flows and the industries' need for natural resources enables the sector to pinpoint actions with the most significant overall impact. To reduce the most damaging aspects and improve the performance of the meat sector, we propose the introduction of several innovative cooling methods.

Apart from quantifying the impact of each measure, these sector maps also allow us to show relationships within the supply chain and easily compare single actions in perspective to the greater whole.

This project was made possible with the cooperation of Nepluvi, VNV, COV, AKSV, and the KNS organizations.

Oct. 11, 2014

Director

Industrial Ecologist

Except Integrated Sustainability

Industrial Ecologist

Except Integrated Sustainability

Communication Strategist

Except Integrated Sustainability

Senior Associate

Except Integrated Sustainability