Journey toward sustainability

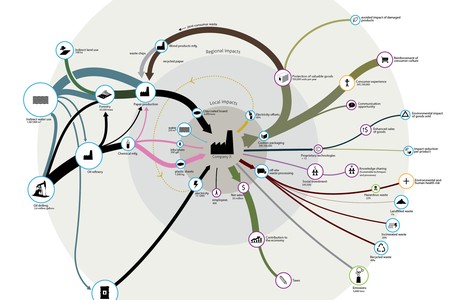

LC Packaging’s vision is to ensure a sustainable future, considering next generations, customers, employees, and manufacturing partners, striving to include all stakeholders in its quest to provide sustainable packaging solutions. The company minimizes the impact on the environment the waste of valuable products while enriching the communities in which it operates.

With a broad international reach, LC Packaging draws resources from the world and converts them into products and services. LC Packaging is aware of its related impact and considers changing its operations and investments to create sustainable value.

LC Packaging identifies four areas of commitment;

- improve the wellbeing of people,

- create supply chain sustainability,

- develop sustainable packaging solutions,

- minimize the impact on the environment.

A compelling journey starts by speaking the same language, gaining insight into key performance indicators, and determining a baseline. Then identifying and prioritizing areas of improvement and communicating about actions.

To minimize the impact on the environment, LC Packaging requested Except to establish baselines for energy and water use, waste generation, and CO2 emissions. Based on our findings, improvement goals were set and integrated into the LC Packaging Sustainability Vision 2022.